| HYBRID n-COAT AS is an advanced coating material which has superior anti-static qualities with surface resistivity of 105~108 Ω/SQ. Its anti-abrasion quality deters electrostatic for a long time and is optimized for reducing electrical errors for precise production and electric measurement. |

|

|

| |

Recommended Use

|

1. Concrete or Epoxy floors in clean room facilities, pharmaceutical factories, operation rooms, etc.

2. Concrete or Epoxy floors in other facilities that require conductivity, high protection against dust, and shock-resistant qualities |

|

| |

Characteristics

|

1. Hybrid coating

2. Anti-static

3. High abrasion-resistance

4. Shock-resistant, water-resistant, chemical-resistant

5. Fouling-resistant |

| |

| Color |

Color |

| Finished Condition |

Not glossy |

| Solid |

60% |

| Hardness |

5H |

| Open time |

30 minutes (20℃) |

| Flashing Point |

Minimum 23℃ |

|

| |

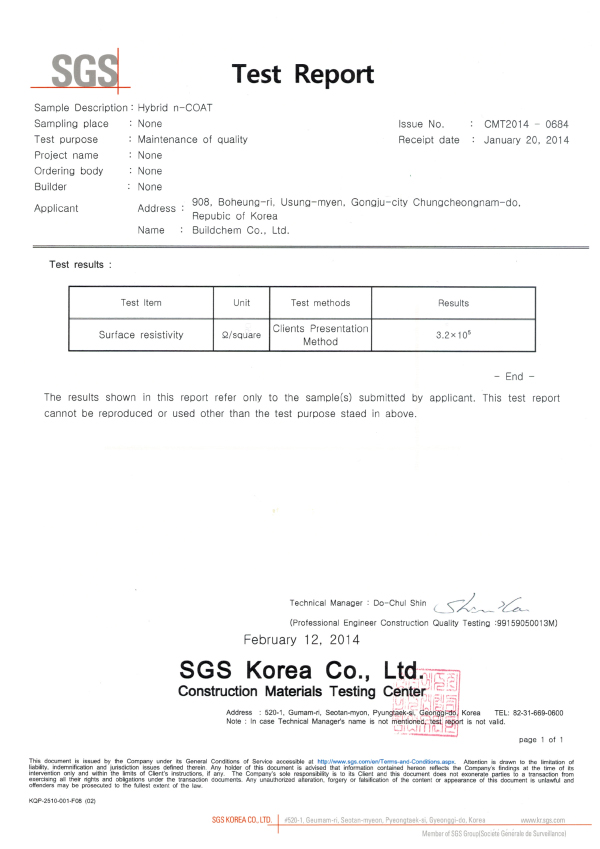

Official test report by SGS Korea

|

| Test Item(s) |

Unit |

Test method used |

Test Result (s) |

| Surface resistivity |

Ω/square |

Clients Presentation Method |

3.2 x 105 |

|

| ※ The result shown above can be changed under different testing conditions |

|

|

| |

Anti-abrasion test result (abrasion reduction:g)

|

| Test No. |

Epoxy |

Epoxy Lining |

n-COAT |

n-COAT AS |

| 1 |

0.3076 |

0.2421 |

0.1926 |

0.1850 |

| 2 |

0.2885 |

0.3155 |

0.1869 |

0.1820 |

| 3 |

0.3049 |

0.2355 |

0.1890 |

0.1880 |

| Average |

0.3003 |

0.2644 |

0.1895 |

0.1850 |

|

|

|

|

| ※ Testing Condition: H-22, 1000g, 500cycles, 3 times each |

| |

PACKING

|

| Main resin: 16kg/can, Hardener 4kg/can |

| |

TEST REPORT

|

|

|